Let’s Start Work

Together

Please feel free to contact us. We will get back to you with 1-2 business days. Or just call us now.

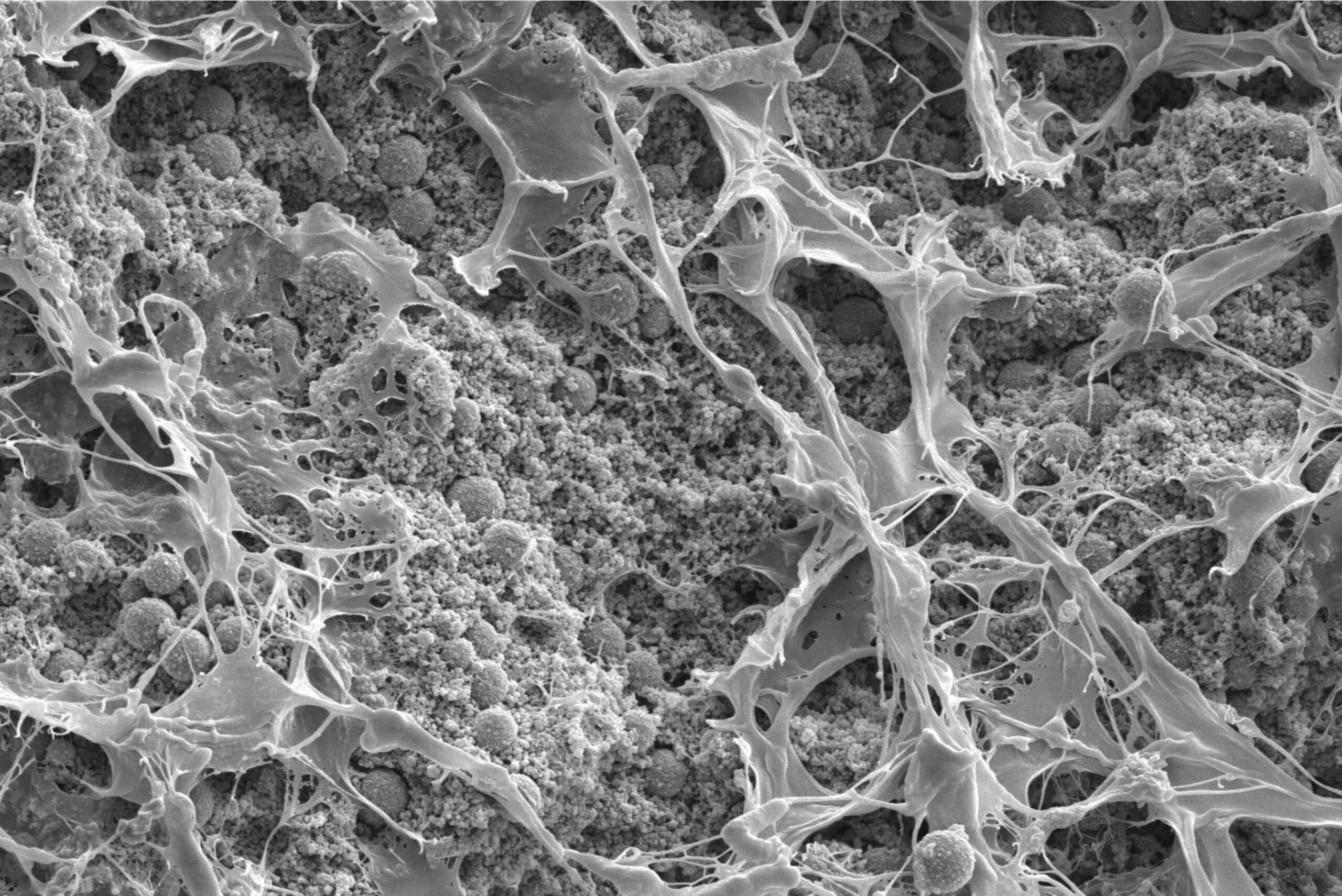

Quantum Dot Tracer Technology

Shraddha Associates’ technology offers the possibility to obtain dynamic zonal production contribution of Oil and Gas reservoirs for years without well intervention. The quantum leap in big data allows better recommendations and decision making in production optimization, increased hydrocarbon recovery, integrity of reservoirs used for gas storage, traceability of hydrocarbons transported in pipelines.

At the heart of the solution is quantum dot tracers responsible for precise indication of each fluid phase — oil, water, and gas — in the production profile, which enables a dramatic increase in the amount of data for well and reservoir performance. Our software offers the possibility to carry out a high-precision and high performance analysis of fluid samples and interpret field data. Our Digital Platform, incorporating Machine Learning and Big Data tools helps to add brand-new value to the digital transformation processes of our valued customers.

What We do:

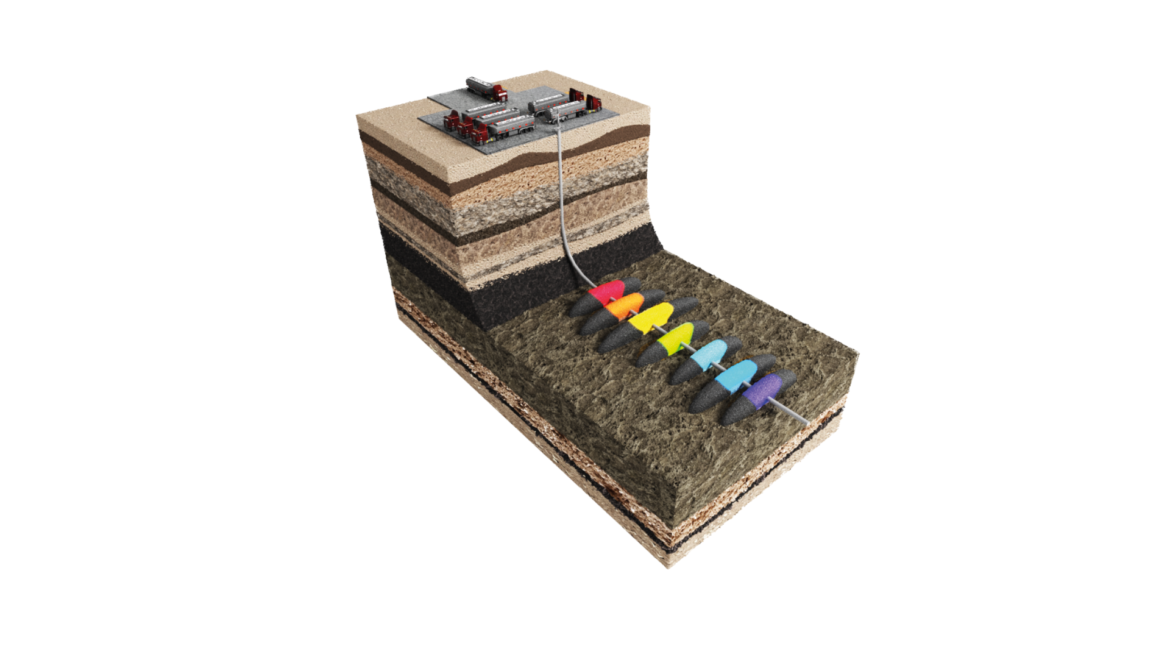

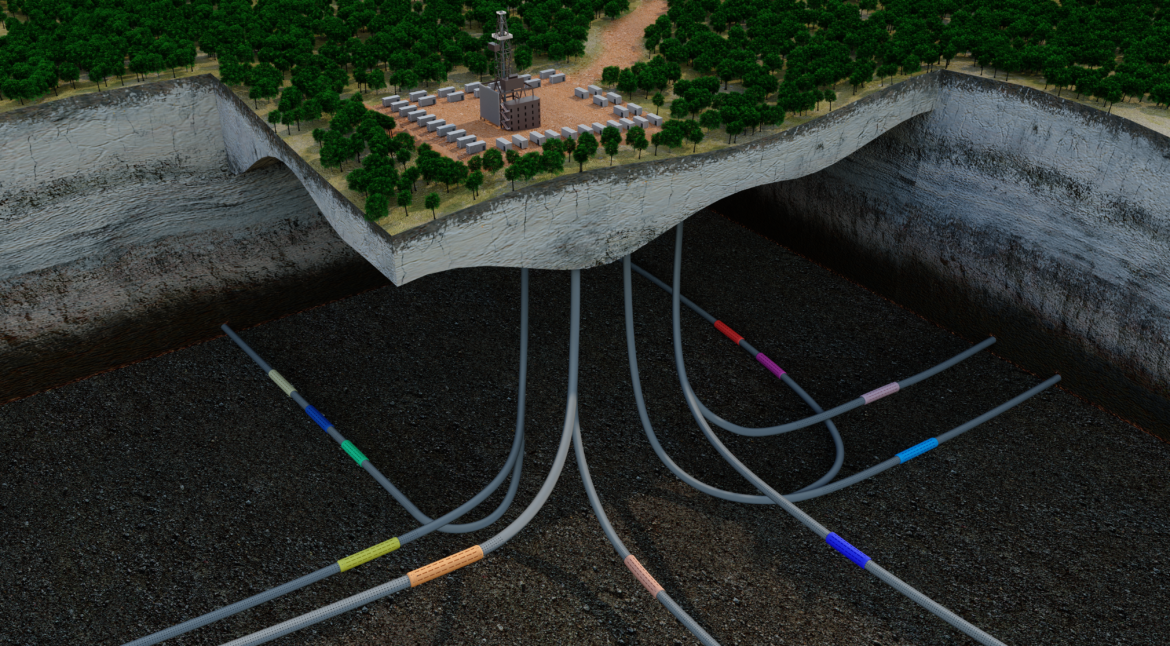

- Long-term production profiling surveillance in horizontal and directional wells.

- Integrated projects for intelligent field development planning based on tracer production profiling data and digital tools for data analysis.

- Integrity diagnostics of underground gas storage facilities.

- Tagging crude oil and oil products for pipeline transportation systems.

- Integrity diagnostics of downhole packers.

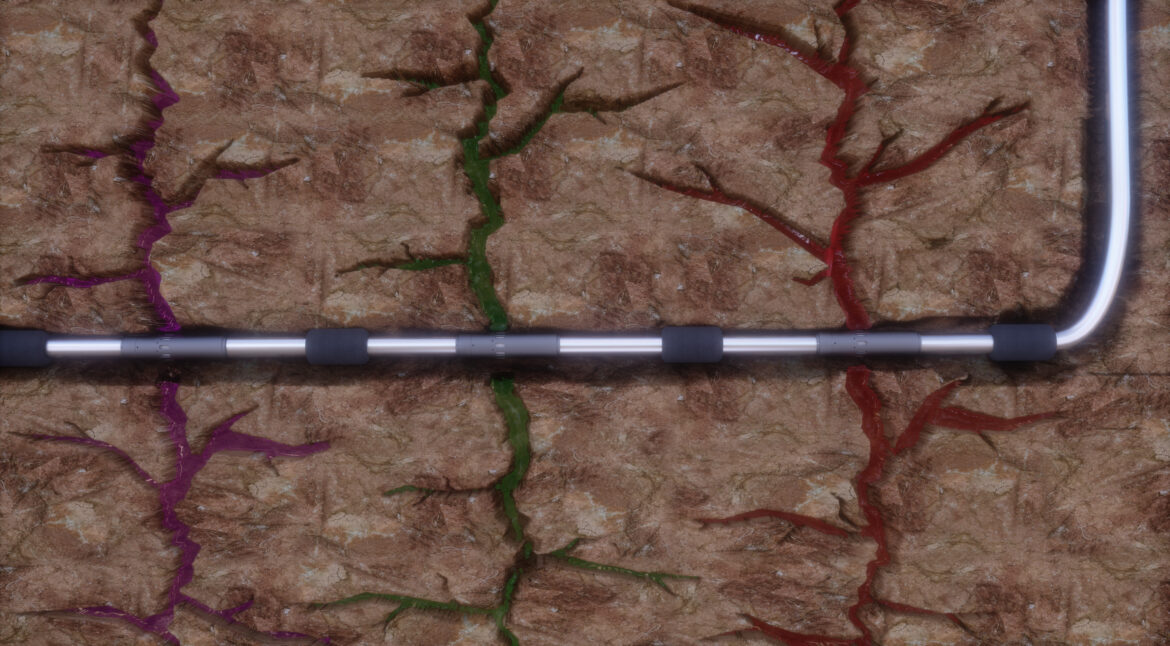

- Estimating hydraulic fracture geometry.

Applications

- Oil, gas and gas condensate wells.

- Groups of wells (field clusters).

- Subsea production units.

- Underground gas storage facilities.

- Pipeline transportation systems.

Advantages of the Technology

- Unlimited number of production profiling cycles for 5+ years surveillance longevity.

- Avoidance of the well shut-off or changes in the well operation parameters during sampling.

- Mitigation of operational and HSE risks.

Value

- Monitoring of water, gas breakthroughs.

- Production or injectivity profile conformance control.

- Improving the hydrocarbon recovery.

- Optimizing the reservoir pressure maintenance system.

- Optimizing well placement, well completion and multistage hydraulic fracturing strategies, including: - optimizing the length of a horizontal wellbore - finding the optimal number of hydraulic fracturing intervals/stages - selecting the optimal multi-stage hydraulic fracturing design and the quantity of injected proppant.

- Improved geological models and monitoring of reservoir integrity in gas storage applications.

- Improved safety and quality of field operations.